Tjänster

Våra medarbetare är passionerade och erfarna. Tillsammans jobbar vi för att leverera framgångsrika projekt inom förnybar energi världen över.

Teknologier

Med de senaste teknologierna bidrar vi till en framtid där alla har tillgång till förnybar energi.

Se alla teknologierResurser

Bläddra bland våra senaste resurser: allt från företagsuppdateringar och branschinsikter till forskningsrapporter och våra partners egna historier.

Se alla resurserKarriär

Bli en del av vårt passionerade team och förändra världen genom meningsfulla och stimulerande uppgifter.

Läs merOm RES

Vi brinner för vårt uppdrag - att förändra hur världen producerar och förbukar energi.

Läs om ossVåra kontor

RES är en global organisation med ett starkt lokalt fokus. Här kan du hitta kontakt- och platsinformation för alla våra RES-kontor.

Kontakta oss-

Startsida

/

Resources

/

Fallstudie

/

Reducing the lead time for a generator exchange

Reducing the lead time for a generator exchange

by RES | maj 15, 2023 | Tid det tar att läsa: < 1 min

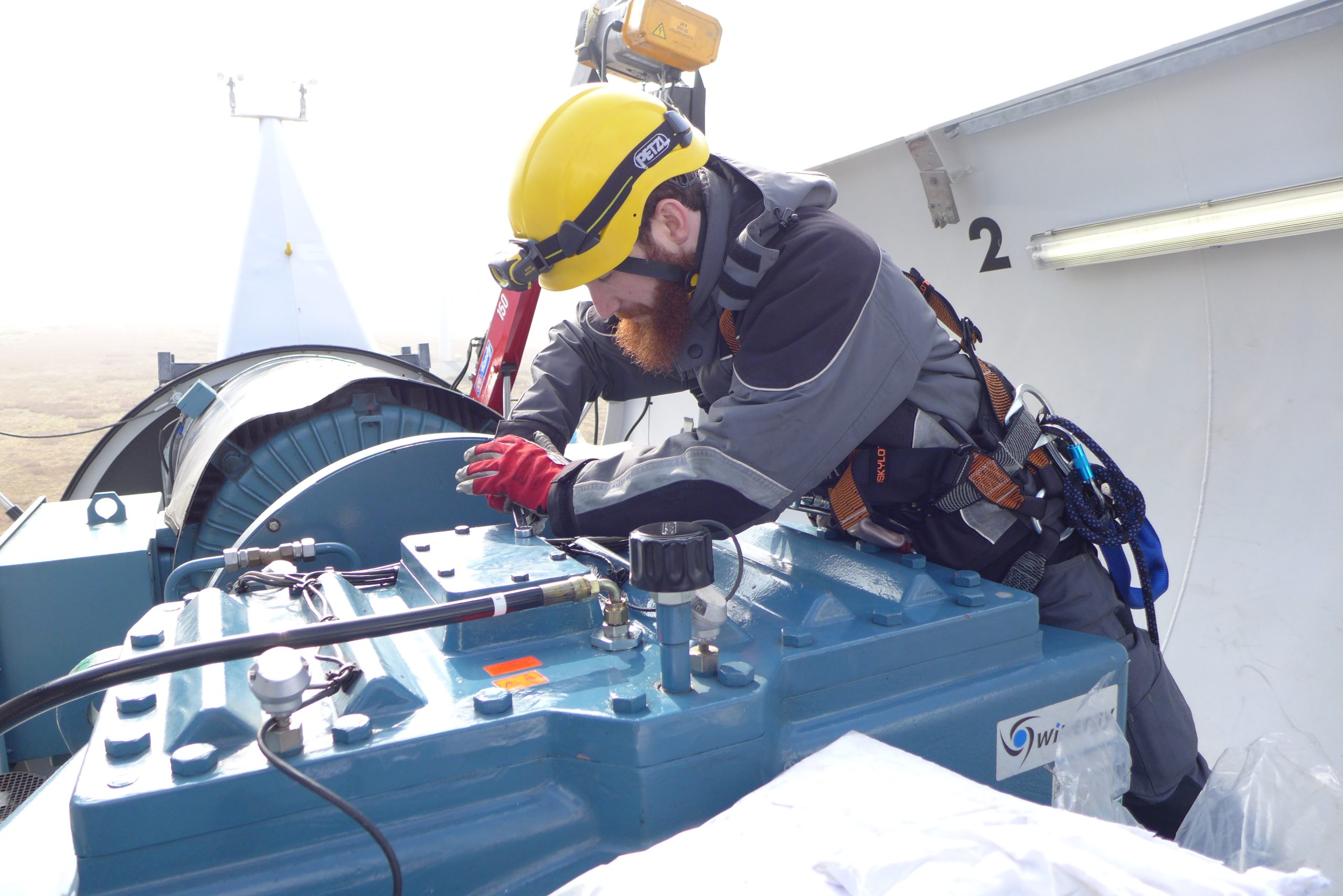

When a generator failed on one of the oldest wind farms in our Asset Management portfolio, RES’ careful planning prevented significant downtime. Due to economies of scale RES is able to procure spares at the lowest cost to the client, and ensure availability.

The work

On this particular site, the turbines aren’t fitted with modern condition monitoring systems, which means our ability to predict failure is diminished, so precautionary measures had been taken in case of faults. The design and specifications for the crane hard-standings had been created in advance to ensure that civil works could begin immediately.

Additionally, a contract was in place with a local generator supplier so that the parts could be sourced straightaway. The replacement generator was brought to site while the RES project management team specified the work required, arranged the contracts and ensured all warranties for the works were in place. RES used its in-house lifting and civil experts as well as our in-house 24/7 Control Centre, to ensure the work was carried out safely.

Results

By strategically planning major component spares, preparing crane hardstand upgrades, and by managing the maintenance from start to finish, we reduced the downtime from potentially 2 months to just 8 days. In this instance we saved the client approximately £14,000 in lost generation.

Our forward planning, monitoring and rapid response often saves clients considerable sums, both in maintenance and lost generation.