Services

Technologies

Promouvoir un avenir énergétique propre grâce à des technologies renouvelables de pointe.

Voir toutes les technologiesRessources

Parcourez nos dernières ressources, notamment les mises à jour de l'entreprise, les témoignages de clients, les informations sur le secteur et les rapports de recherche.

Voir toutes les ressourcesCarrieres

Rejoignez une équipe collaborative de personnes passionnées qui s'engagent dans un travail qui a du sens.

CarrieresÀ propos de RES

Nous vivons notre mission, nous mettons en avant les personnes qui la réalisent et nous célébrons les transformations qui changent la façon dont le monde produit et consomme l'énergie.

Voir à propos de nousEmplacements et bureaux

Tout comme notre entreprise, nous sommes véritablement mondiaux – mais fièrement locaux. Trouvez les coordonnées et l’emplacement de chaque bureau RES.

Nous contacter-

Accueil

/

Resources

/

étude de cas

/

Reducing the lead time for a generator exchange

Reducing the lead time for a generator exchange

by RES | Mai 15, 2023 | Temps de lecture: < 1 min

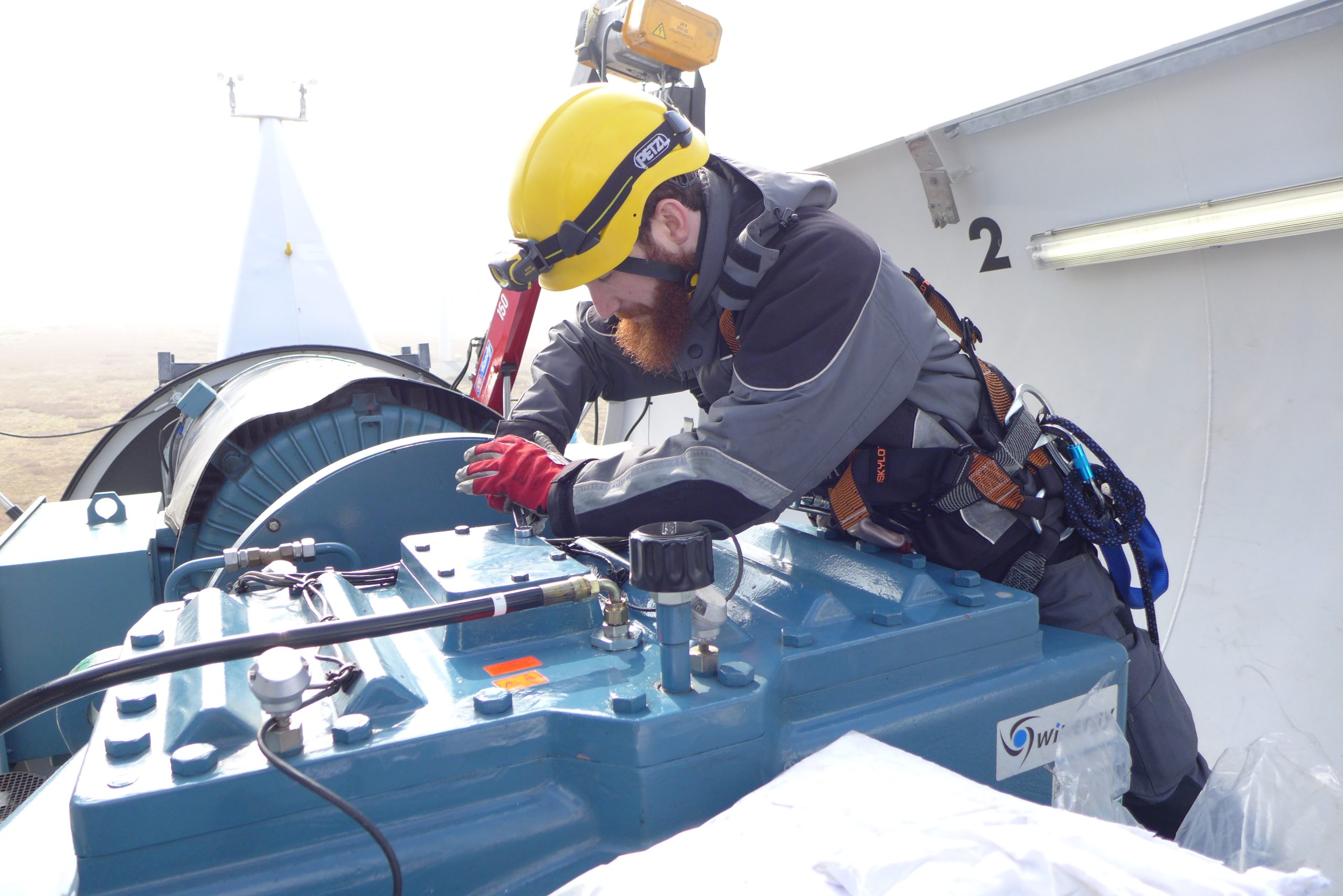

When a generator failed on one of the oldest wind farms in our Asset Management portfolio, RES’ careful planning prevented significant downtime. Due to economies of scale RES is able to procure spares at the lowest cost to the client, and ensure availability.

The work

On this particular site, the turbines aren’t fitted with modern condition monitoring systems, which means our ability to predict failure is diminished, so precautionary measures had been taken in case of faults. The design and specifications for the crane hard-standings had been created in advance to ensure that civil works could begin immediately.

Additionally, a contract was in place with a local generator supplier so that the parts could be sourced straightaway. The replacement generator was brought to site while the RES project management team specified the work required, arranged the contracts and ensured all warranties for the works were in place. RES used its in-house lifting and civil experts as well as our in-house 24/7 Control Centre, to ensure the work was carried out safely.

Results

By strategically planning major component spares, preparing crane hardstand upgrades, and by managing the maintenance from start to finish, we reduced the downtime from potentially 2 months to just 8 days. In this instance we saved the client approximately £14,000 in lost generation.

Our forward planning, monitoring and rapid response often saves clients considerable sums, both in maintenance and lost generation.